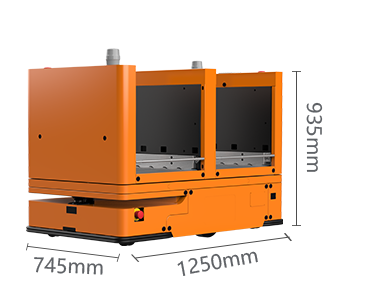

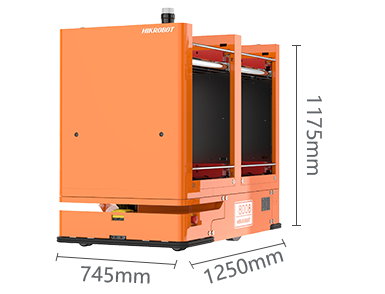

Conveyor&Transmission Series support docking with machine, transmission line or tooling mechanism to fulfill the automated production needs. It has been optimized the obstacle avoidance, positioning accuracy and material testing.

| Dimension L*W*H (mm) | 1250*745*935 |

| Transferred Method | Rollers |

| Weight (kg) | 350 |

| Angular Accuracy (°) | ±1 |

| Positioning Accuracy (mm) | ±10 |

| Run time (h) | 8 |

| Dimension L*W*H (mm) | 1250*745*1175 |

| Transferred Method | Rollers |

| Weight (kg) | 410 |

| Angular Accuracy (°) | ±1 |

| Positioning Accuracy (mm) | ±10 |

| Run time (h) | 8 |

The Latent Tractor AMR dives into the bottom of the racks and pulls the racks by means of traction pins, and can pull one or more racks at the same time for efficient handling.

| Dimension L*W*H (mm) | 1615 × 470 × 285 |

| Transferred Method | Traction |

| Weight (kg) | 240 |

| Angular Accuracy (°) | ±1 |

Heavy-Duty Lifting Series support large material transferring, mainly used for arge/medium-scale materials transferring in automobile, machinery manufacturing PV and lithium battery industry.

| Dimension L*W*H (mm) | 1900*1200*370 |

| Transferred Method | Lifting |

| Weight (kg) | 800 |

| Angular Accuracy (°) | ±1 |

| Positioning Accuracy (mm) | ±10 |

| Run time (h) | 8 |

| Dimension L*W*H (mm) | 2000*1400*480 |

| Transferred Method | Lifting |

| Weight (kg) | 900 |

| Angular Accuracy (°) | ±1 |

| Positioning Accuracy (mm) | ±10 |

| Run time (h) | 8 |

The company is a new enterprise engaged in developing, producing and selling solar cells and battery packs. Working with ERP, MES, and other upper-layer systems, our solution integrated with onsite equipment well, enhanced the automation